Boiler Operation Made Easy : Procedure for

Starting and Stopping a Boiler

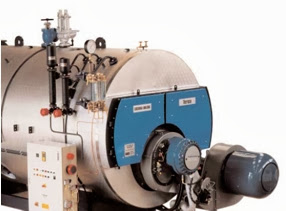

A boiler is one of those

machineries that gets the ship going. A boiler is something, which though not

required continuously in operating a ship, cannot be done away with. Moreover,

it’s a dangerous equipment which generates steam at extremely high pressure,

and it is for this reason that proper care should be taken while operating it.

In this article we

have brought to you a step-by-step procedure for starting and stopping a boiler

on a ship. With this procedure you can never go wrong, as far as boilers are

concerned. Starting and stopping a boiler was never so easy.

Starting a Boiler

It is to note that the

following steps may not apply to all types of boilers and each boiler requires

some additional steps to be followed as per its system design. However, the

basic steps remain the same:

1.

Ÿ Ensure that the vent valve on the boiler is open and check

there is no pressure in the boiler.

2.

Ÿ Check that the steam stop valve is closed.

3.

Ÿ Check that all the valves for fuel are open, and let the fuel

circulate through the system until it comes to the temperature required by the

manufacturer recommendation.

4.

Ÿ Check and open the feed water valves to the boiler and fill the

water inside the boiler drum to just above the low water level. This is done

because it is not possible to start the boiler below the low water level due to

safety feature which prevent boiler from starting. Also, the level is not

filled much because if filled too much, the water inside the boiler might

expand and over pressurize the boiler.

5.

Ÿ Start the boiler in automatic mode. The burner fan will start

the purging cycle which will remove any gases present in the furnace by forcing

it out through the funnel.

6.

Ÿ After the pre-set purge time the pilot burner will ignite. The

pilot burner consists of two electrodes, through which a large current is

passed, via the transformer, producing the spark between the electrodes. The

pilot burner is supplied with diesel oil and when the oil passes over, the

former ignites.

7.

Ÿ The main burner which is supplied by heavy oil catches fire

with the help of pilot burner.

8.

Ÿ Check the combustion chamber from the sight glass to ensure the

burner has lit and the flame is satisfactory.

9.

Ÿ Keep a close eye on the water level as the pressure increases

and open the feed water when the level of water inside the gauge glass is

stable.

10.

Ÿ Close the vent valve after the steam starts coming outside.

11.

Ÿ Open the steam stop valve.

12.

Ÿ Once the working steam pressure is reached, blow down the gauge

glass and float chambers to check for the alarms.

Stopping a boiler

1.

Ÿ If the boiler is needed to be stopped for longer duration for

maintenance or opened up for survey, change the fuel to distillate fuel.

2.

Ÿ If separate heating arrangement for heavy oil is present then

there’s is no need to

change over to distillate fuel and the oil is kept on circulation mode.

3.

Ÿ Stop the boiler automatic cycle.

4.

Ÿ Close the steam stop valves.

5.

Ÿ Close the boiler feed water valves.

6.

Ÿ When the boiler pressure is just reduced to over atmospheric

pressure the vent valve is kept open to prevent vacuum formation inside the

boiler.

Boiler Starting Failure – Troubleshooting

Failure in

boiler starting is a common phenomenon on ship. There can be several reasons

for the failure in staring of a boiler. In this article we will learn about the

most common reasons for not starting of boiler.

1) Fuel inlet valve to the burner

is in close position:

The fuel line for

boiler’s burner consists of several valves located at fuel tank, pumps suction,

discharge valve, or valve before the boiler burner. Any of these can be in

closed position resulting in starvation of fuel.

2) Line filter at the

inlet of the fuel line for burner is choked:

If the system runs in

heavy oil then there are chances of filters in the line getting choke. To avoid

this, boiler system are normally built for changeover from diesel to heavy oil

during starting and heavy to diesel during stopping. This keeps the filter and the

fuel line clean.

3) Boiler fuel supply pump is not

running:

There are two main

reasons for fuel pump not running. Normally when the pumps are in pairs, the

change over auto system is kept in manual position, and if the operating pump

trips, the stand by pump will not start automatically. Another reason is

tripping of pump due to short circuit in the system etc.

4) Solenoid valve in the fuel

supply line is malfunctioning

Nowadays most of the

system adopts advance automation, but their can be a possibility wherein the

solenoid in the fuel supply line is malfunctioning and not opening.

5) Flame eye is malfunctioning:

A Flame eye is a photocell operated flame sensor fitted directly

on the refractory to detect weather the burner is firing or not. If the flame

eye unit is malfunctioning, then it will give a trip signal even before the

burner starts firing.

6) Air or Steam ratio setting is

not proper

For proper and

efficient combustion, air fuel ration is very important, if the supply of air

is excess then there will be excess of smoke, and if it exceeds more than

normal level the combustion will burn off causing flame failure.

7) Forced draft fan flaps

malfunctioning

For removing excess

gases trapped inside the combustion chamber forced draft fan (FDF) are used for

pre purging and post purging operation and are connected with a timer to shut

the fan flaps. If the flaps are malfunctioning then continuous forced air will

go inside the chamber, preventing the burner to produce flame causing flame

failure of the boiler.

8) Any contactor switch

inside Control panel is malfunctioning

Boiler control panel

consist of several contactors and PLC cards. Even one contactor malfunctioning

may result in trouble for boiler starting.

9) Trip not reset

If any previous trips

like low water level, flame failure, emergency stop etc. has not been reset

than boiler will not start.

10) Main Burner atomiser is clogged

Main burners consist

of atomizer for efficient burning of fuel. If the atomizer is clogged by sludge

and fuel deposits then burner may not produce flame and trip the boiler..

11) Pilot Burner nozzle is choked :

A Pilot burner nozzle

is very small and can be blocked by carbon deposits and sludge resulting in

flame failure. Some pilot burner consists of small filter which can be clogged

after continuous operation resulting in flame failure because of carbon

accumulation.

12) Electrodes are not generating

spark

Initial spark for

generating a flame is produced by electrode which may be due to carbon deposits

on them or fault in the circuit of electrodes etc.

Important Points for Boiler Cleaning on a Ship

Boiler

cleaning is one of the most important processes that are to be performed

routinely on marine boilers on a ship. Boiler cleaning is done to prevent and

remove carbon and particle deposits from the boiler.

However, there are

certain important points that are to be kept in mind while doing boiler

cleaning. In this article we learn about these important points.

Boiler Cleaning: Important

Points

§

If the boiler water is treated

properly with chemicals and the concentration of chemicals is within the

acceptable range then the deposits on the walls of water and steam side of the

boiler will be minimal.

§

If boiler is operating on fresh water

rather than heavy water the deposits inside the tubes will also be minimal and

can be removed by boiling out. The hard deposits inside the tubes are removed

with the help of scrubber and brush from the upper drum.

§

If the boiler oil burner is

functioning properly and proper maintenance is being carried out from time to

time then the soot deposits inside the oil fired boiler will be minimal. But

the soot deposits cannot be completely avoided as during starting of boiler

soot formation is more and over a period of time it collects inside the boiler

space.

§

The soot deposits can be removed with

the help of water washing with 10 percent soda solution through the inlet door

in the uptake with the help of water hose.

§

Necessary precautions are to be taken

during water washing. It is to be noted that the refractory present inside the

boiler does not get wet.

§

During water washing the refractory

should be covered with the plastic sheet and water should be drained off

continuously through the drain provided at the bottom.

§

In case the refractory gets wet, the

lighting of boiler should be done very slowly, otherwise the refractory will

crack and drop down and finally cause overheating and deformation inside.

The above mentioned

points are the basic things to be kept in mind while doing boiler irrespective

of the type boiler or ship.

Procedure for Boiler Gauge Glass Maintenance on a Ship

A gauge gauge

is used at many places on a ship. Gauge glass is a kind of a level indicator

which shows the amount of fluid in a tank or any other storage place on a ship.

In this article we will learn as to how the maintenance of a gauge glass is

done on a ship. Gauge glass are mainly used in boiler of the ship.

Before learning about

boiler gauge glass maintenance lets take a quick look at the working of a gauge

glass.

Working of Boiler Gauge Glass

A gauge glass has two

different compartments – top side and bottom side, connected to two different

sections of a boiler. The top side of the gauge glass is connected to the steam

side of the boiler and the bottom side is connected to the water side of the

boiler. The pressure on both sides will equalize and the level of water can be

seen in the gauge glass.

Maintenance During service

check up.

Refer the diagram for

better understanding of boiler gauge glass.

§

Check the nut (1) and tighten if

necessary.

§

Bolts on the boiler flanges are to be

checked, if loose tighten them.

§

Check if union nuts are loose.

§

Bolt from screw 7 with cocks in open

position.

§

If the leak can not be stopped from

water side on the gauge glass by tightening the screw 7 then the sealing

surface of the cock plug 8 my be damaged or corroded.

Gauge glass blow down procedure

Gauge glass should be

blown before lighting up of boiler, after stopping the boiler and regularly if

the level in gauge glass is suspected to be wrong.

Cleaning the water side of

gauge glass

§

Close the valve S and W as shown in

the figure.

§

Now open the cock W and see if the

water is coming out of the drain valve D indicating the drain line is clear.

§

Now close the drain valve D and keep

the cock W open and see if the water level rises in the gauge glass; this

indicates the line to gauge glass is also clear.

§

Repeat the steps two to three times

to remove nuds and deposits inside.

Cleaning the steam side of

gauge glass

§

Close both the cocks S and W.

§

Now open the cock S and open the

drain valve D and see the steam is coming out. The drain is opened only for 1-2

seconds only as steam may damage the sealing and service life decreases.

Putting the gauge glass in

normal operating position

§

Close all the valves S, W and the

drain valve D.

§

Now open the cock W and let the water

fill inside the gauge glass.

§

Now open the cock S and then the

level can be seen as the pressure equalizes.

Boiler Mountings: A Comprehensive List

Just

installing a boiler on a ship doesn’t guarantee efficient working of a boiler.

There are several mountings and attachments required to be fitted on the boiler

to ensure its safety and quality performance. The article describes a

comprehensive list of boiler mountings without which a boiler cannot operate on

a ship.

Boiler operation can

be carried out safely and efficiently by only using the mountings described

below:

1) Main steam Stop Valve: The steam generated in the boiler is

supplied to the main system through this v/v. It is normally non-return type of

valve.

2) Auxiliary steam Stop Valve: If there is separate steam line provided for

small auxiliary system, it is supplied through this valve. The valve is smaller

in size and usually of a non-return type.

3) Safety valve: In the event of unsafe excessive pressure

inside the boiler, the safety valve comes in action to release the

overpressure. The lifting pressure of the valve is set prior to its

installation and locked in the presence of a surveyor so that it not changed

later on. Safety valves are generally installed in pairs.

4) Water level gauge glass: Gauge glasses are also fitted in pairs for

manually checking the water level inside the boiler drum. It is on the basis of

the boiler pressure that the construction of the gauge glass is decided.

5) Air release valve or boiler

vent: This valve is fitted

in the headers, boiler drum etc, to avoid imploding of boiler when it is

depressurized or when initially raising the steam pressure.

6) Feed check and control v/v: This valve controls the supply of steam

supply as per the demand and is fitted in both main and aux steam line after

the stop valve. They are non-return valves with a visible indication of open

and close position.

7) Pressure gauge connection: This pressure gauge can be fitted in super

heater, boiler drum and wherever it is necessary to read the pressure reading.

8) Blow down valve: It is used to empty the boiler completely

for maintenance purpose or for water treatment of boiler when the chloride

level becomes very high.

9) Scum blow down valve: It’s a shallow dish type arrangement fitted

at the normal water level which allows the blow down of floating impurities,

oil foaming etc from the water surface.

10) Sampling connection: Generally, a sampling water cock arrangement

is also fitted with cooler in series so that water sample can be collected at

any time for feed water analysis.

11) Whistle valve: If there is a provision for steam whistle in

the ship, then steam is supplied directly from the boiler through a small bore

type non-return valve known as whistle valve.

12) Low Level alarm: A device used to initiate audible warning at

low water level condition.

13) Soot blowers: Required to blow the soot and the combustion

products from the tube surfaces. It is operated by steam or compressed air.

14) Automatic feed water regulator: Device which is essential to ensure

appropriate water level in all load conditions and is fitted in the feed line.

Multiple element feed water control system is used in boilers with high

evaporation rate.

The Science behind Marine Boiler Water Circulation on Ships

The most

important aspect of any marine boiler is maintaining the correct water level.

As the boiler fires, steam liberates from the surface of the water and thus as

the steam gets consumed, there is subsequent drop in water level inside the

boiler.

Steam gets produced only when there is an effective circulation

of water within the boiler. For tank type boilers, circulation is not

distinct and the water circulates within the tank of the boiler itself. For

water tube boilers, circulation is necessary within each and every tube and

headers.

This happens naturally

if both the steam and water drums are connected with tubes. But there is some

basic design reason which has to be emphasized on.

Natural Circulation within a

Water Tube Boiler:

The steam drum and

water drum may or may not be separated depending upon the boiler design. To

understand the water circulation principle, we will assume the following

components to be separate. A steam drum at the top is connected to the water

drum at the bottom through down comers outside the boiler shell and risers

inside the boiler shell.

Cold water is fed to the top drum/steam drum, by water

feed pump through a screw down non-return valve

and a check valve. As we all know, hot water stays on top and relatively cold

water (being denser) travels to the bottom of the drum.

The steam/water drum

has down comers connecting to the water ring at the bottom of the boiler. The

down comers are located outside the boiler shell and are large in diameter when

compared to the water tubes.

As the cold water from

the down comers reach the water ring in the bottom, the circulation starts

within the tubes and drums. As the water particles enter the water tubes, which

are inside the boiler furnace, they start to heat up and become wet steam with

some bubbles. As they are less dense, they immediately rise up to the steam

drum and thus are continuously being replaced by relatively cold water from

down comers. Thus circulation happens naturally inside a water tube boiler.

Design Aspect

If the circulation has

to happen in a natural way, then there are some design considerations to be

observed. Ratio between the amount of steam leaving the risers & the amount

of water entering the down comers is of the order 4:1.

It is important to

have more water than steam on the risers. If the riser at some point becomes

completely full of steam, the tube would over heat and “BURN OUT”.

“BURN OUT” is where

the tube metal over heats can no longer resist the pressure forces within the

tube and thus ruptures.

Reasons for having External

Down comers:

It is known that as

the pressure and temperature increases, the density of water decreases. Thus

the density difference between water and the steam reduces & thus at higher

pressures, the natural circulation of water-steam is impaired.

Thus to maintain the

natural circulation, external, unheated down comers are fitted. These external

down comers are large bore tubes connecting the steam drum with the water drum.

Very informative! The effort is truly appreciated! I would like to link this blog to my free websites marine-electricity.com and marineelectricity.com. :)

ReplyDeleteIts like you read my mind! You appear to know so much about this, like you wrote the book in it or something. I think that you can do with some pics to drive the message home a bit, but other than that, this is fantastic blog. A fantastic read. I will certainly be back.

ReplyDeleteBoiler sizes industrial

Fantastic post however I was wanting to know if you could write a litte more on this subject? I'd be very grateful if you could elaborate a little bit more. Many thanks!

ReplyDeleteBoiler sizes industrial

Amazing this post.

ReplyDeleteMarine Water Heater

Marine Tankless Water Heater

Everyone loves what you guys tend to be up too. This type of clever work and reporting! Keep up the awesome works guys I've you guys to our blogroll.

ReplyDeleteBiomass boiler

high pressure water tube boiler (also spelled water tube) is a type of boiler in which water circulates in tubes heated externally by the fire. Fuel is burned inside the furnace, creating hot gas which heats water in the steam generating tubes.

ReplyDeleteBoiler cooling treatment in Ontario Canada

I'm really enjoying the theme/design of your web site. Do you ever run into any browser compatibility problems? A number of my blog audience have complained about my website not working correctly in Explorer but looks great in Opera. Do you have any suggestions to help fix this issue?

ReplyDeleteSteam boiler

I am extremely impressed with your writing skills and also with the layout on your blog. Is this a paid theme or did you customize it yourself? Either way keep up the nice quality writing, it is rare to see a nice blog like this one these days..

ReplyDeleteRepair boiler Richmond

I have to show my thanks to you just for bailing me out of this particular dilemma. After looking out through the world-wide-web and getting tricks which are not pleasant, I believed my entire life was well over. Existing devoid of the strategies to the difficulties you have resolved by way of your entire short post is a critical case, and the ones that could have adversely damaged my career if I had not noticed the website. Your main mastery and kindness in dealing with almost everything was invaluable. I don't know what I would've done if I had not come across such a solution like this. I can at this moment look forward to my future. Thanks a lot very much for this specialized and sensible guide. I won't be reluctant to refer your web site to any person who needs guidance on this issue.

ReplyDeleteSteam generator

Howdy! Would you mind if I share your blog with my facebook group? There's a lot of folks that I think would really appreciate your content. Please let me know. Thank you

ReplyDeleteRepair boiler Richmond

Not only this, you can know more about the Wet Scrubber in Faridabad by reading this post. In this post, you will get to know some new facts about this scrubber. Also, Clear Ion Experts has the answer to every query so visit them for any answer.

ReplyDeleteIntroduce myself, I'm Ridwan. I used to work in several boiler fabrication companies, where I served as a technical support specialist in boiler systems. I hope to be able to share my experiences in the future. If you encounter any difficulties with troubleshooting, setting boiler burners, or conducting emissions gas tests, please feel free to visit my website. Thank you. https://boilerbagus.com

ReplyDelete